Main Page

A.A. Martinos Center / Wald group anthropomorphic phantom builder's Wiki

This Wiki is a resource for people interested in constructing anthropomorphic MRI phantoms developed by Larry Wald's group at the Martinos Center for Biomedical Imaging, Massachusetts General Hospital.

The basic principle is that improved anthropomorphic phantoms lead to better and faster development of MRI methodology with less use of healthy subject volunteers. This is both cost effective and ethical. Therefore we distribute our designs and ask only that you reference the appropriate paper and the source of the design.

Designs are available in standard CAD format are intended to be 3D printed. Most of the components are open source designs.

MGH 3D-printing CAD phantoms for download

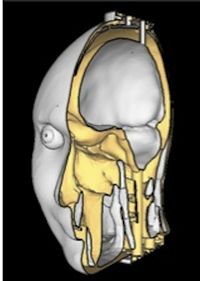

- MGH head phantom

- MGH "Angel 001" head phantom with realistic B0

- MGH "Angel 002" head phantom with realistic B0 (re-fillable brain compartment)

- MGH fetal phantom version 1

MGH voxel numerical models for download

- MGH "Angel 001" voxel head model

- MGH "BoMA" voxel head model

- MGH "HS1" voxel head + chest model (female, medium size)

- MGH "HS3" voxel head + chest model (male, large size)

- MGH "HS4a" voxel head + chest model (female, large size)

- MGH "HS6" voxel head + chest model (male, large size)

- MGH "DCA" detailed voxel head model (female, medium size)

- DBS Virtual Population

3D-printed phantoms construction tips

This section contains general instructions for making 3D printed phantoms. More detailed/specific instructions may be available on the individual phantoms webpage.

3D printing

Once you have downloaded the CAD files for a specific phantom, 3D print them. Note that some parts may require you to be able to dissolve the support material, which is not possible on all 3D printers. This is most important for complex parts (e.g., skull) with many grooves and cavities that are not be easily reachable. If you do dissolve the support material using a solvent, make sure that the parts are clean and perfectly dry before continuing the phantom making process (this may require leaving them in a well-ventilated area for one or two days).

When used for MRI, the plastic parts must be completely free of air cavities. Therefore, it is important that all parts are printed as "dense" as opposed to "sparse". Although the "sparse" option results in faster printing and smaller volumes of plastic being used for each phantom, the presence of air cavities in the plastic parts will create off-resonance effects that may render the phantom useless. It is our experience that printing all plastic parts as "dense" is an absolute necessity at 7 Tesla.

Waterproofing

The next step is to seal the printed parts. Even if your 3D printer offers a "waterproof" printing option, in our experience this does not mean that the parts will actually be waterproof... 3D printing of waterproof parts is difficult. Mostly, the "waterproof" 3D printing options available on some printer work only for parts that are flat and don't have any complex details (e.g., flat panels). These almost always fail for complex geometries such as a human head. We have experimented with several techniques for waterproofing phantoms including painting the plastic parts with epoxy and melting of the plastic surface with a solvent (acetone can be used to melt ABS parts. Methylene chloride can be used to melt polycarbonate plastic). We have found that these two methods do not work well however. The method that we currently use for all our models at MGH consists in spraying the parts with a rubber spray. For our phantoms, we apply three thick coats of rubber spray on the outside and the inside of all parts (covering the outside of the outer parts prevents leaks and sweating in the event where some water infiltrates the plastic parts because of failure of the inner-most rubber coat). We use a red rubber spray as opposed to a black one since the latter color is often achieved using ferrite particles that may be magnetic. Note that the parts must be entirely sealed with spray before assembly (inside and outside surface), including the small grooves and nudges used for assembly of matching parts (for good mating of complementary parts after coating with the rubber spray, we have left some room between the matching grooves and nudges in the CAD models).

We have had success with the following aerosol spray rubber coating (3 or 4 coats):

Performix 11201 Plasti Dip Red Multi-Purpose Rubber Coating Aerosol - 11 oz. (Red)

McMaster Carr weblink for Plasti-Dip rubber spray

The red spray works the best.

Assembly

Once all parts are waterproofed, simply assemble them by gluing them with epoxy. Apply a small pressure between the two parts during curing to ensure a good seal. If the phantom contains nested parts (e.g. a skull compartment inside an outer plastic shell), assemble the inner compartment first and the outer second. Also, if the filling port of the inner compartment does not extend outside the phantom do not forget to fill the compartment before assembling the outer compartment!

Filling

The final step consists in filling the various compartments with tissue-mimicking gel. We use the following mixture (all concentrations are in percent of total weight):

- Agar: 1% to 3% depending on the desired viscosity. When mixed with water, a 1% agar solution has a tick but liquid consistency. A water-based 3% agar solution is solid at room temperature.

- Gadolinium: 0.1%, this is useful to reduce T1 and hence allows faster testing of protocols (short TR).

- Salt (NaCl): This is required for increasing the conductivity of the mixture and hence loading of the coil. See the graph on the right to determine the appropriate concentration.

- Sodium Azide (NaN3): 0.05%, this is used to prevent bacterial growth. (Use caution working with NaN3 as it is highly toxic. Do not let NaN3 solution contact skin. Also avoid exposing the powder or solution to metal objects, which can generate toxic gas)

Additionally, one can add ethylene glycol form to lower the permittivity (the mixture above has a permittivity close to that of water, i.e. ~80, which is greater than the permittivity of biological tissues, i.e. ~50). The proper concentration of ethylene glycol should be determined using a dielectric probe. In our experience, lowering the water permittivity to tissue-levels requires large amounts of ethylene glycol. This may change other parameters of the mixture such as its consistency and its conductivity. In order to prepare the mixture, we recommend the following step-by-step process:

- Heat the water in glass containers using a microwave oven until the water boils.

- Add all the ingredients except the agar and mix well.

- If you kept the water hot using a hot plate, turn it off (otherwise you will burn the agar at the bottom of the container). Slowly pour the agar powder in the hot mixture while stirring continuously to avoid the formation of large lumps of undissolved agar. Note that for the agar to dissolve well, the water temperature should be at least 80 degrees Celsius.

Before filling the phantom you may want to wait an hour or two so that the mixture cools and doesn't damage the waterproof rubber coating. Also keep in mind that agar shrinks in volume as it cools down. To completely fill the phantom compartments, wait until the agar mixture completely cools and then complete filling with some of the leftover mixture. Finally, seal the compartment using hot glue.

References

[http://www.ncbi.nlm.nih.gov/pubmed/17659546 Design, Construction and Evaluation of an Anthropomorphic Head Phantom With Realistic Susceptibility Artifacts

[http://www.ncbi.nlm.nih.gov/pubmed/3821466 New Polyvinyl Alcohol Gel Material for MRI Phantoms

[http://www.ncbi.nlm.nih.gov/pubmed/16148391 Tissue-mimicking phantom materials for narrowband and ultrawideband microwave applications

[http://www.ncbi.nlm.nih.gov/pubmed/22396226 A Novel MRI-Compatible Brain Ventricle Phantom for Validation of Segmentation and Volumetry Methods

[http://www.ncbi.nlm.nih.gov/pubmed/21866208 Heterogeneous Anthropomorphic Phantoms With Realistic Dielectric Properties For Microwave Breast Imaging Experiments

[http://www.ncbi.nlm.nih.gov/pubmed/22225325 An anthropomorphic polyvinyl alcohol brain phantom based on Colin27 for use in multimodal imaging